Worst-Case Rigidity Analysis and Optimization for Assemblies with Mechanical Joints

Computer Graphics Forum (Eurographics 2022)

🧱 LEGO models (and more assemblies) made structurally rigid

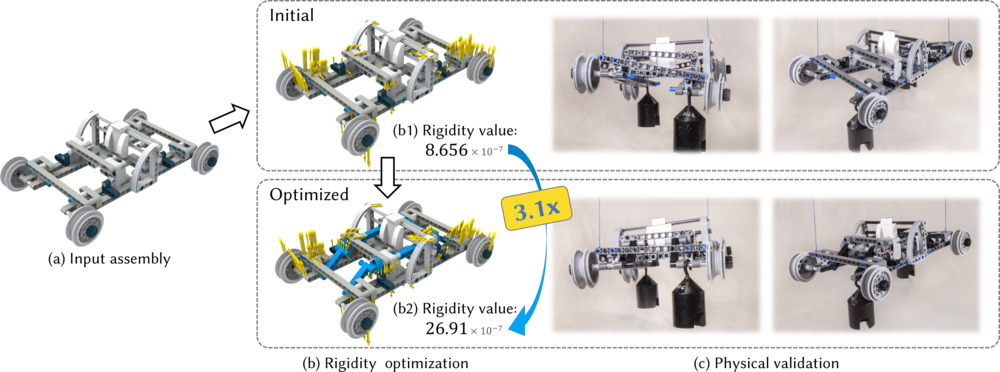

Given the assembly structure of the LEGO Technic ROLLING CHASSIS (a), our method quantifies the rigidity of the structure (b1) and finds the worst-case external load configuration (yellow arrows) that maximally deforms it (c). After we strengthen the initial model as per the recommendation given by our method, the reinforced model (b2) has its rigidity value tripled, and undergoes less deformation under the same loads. The physical experiments (c) show results that align with the analysis of our method.

Abstract

We study structural rigidity for assemblies with mechanical joints. Existing methods identify whether an assembly is structurally rigid by assuming parts are perfectly rigid. Yet, an assembly identified as rigid may not be that “rigid” in practice, and existing methods cannot quantify how rigid an assembly is. We address this limitation by developing a new measure, worst-case rigidity, to quantify the rigidity of an assembly as the largest possible deformation that the assembly undergoes for arbitrary external loads of fixed magnitude. Computing worst-case rigidity is non-trivial due to non-rigid parts and different joint types. We encode parts and their connections into a stiffness matrix, in which parts are modeled as deformable objects and joints as soft constraints. Based on this, we formulate worst-case rigidity analysis as an optimization that seeks the worst-case deformation of an assembly for arbitrary external loads. Furthermore, we present methods to optimize the geometry and topology of various assemblies to enhance their rigidity, as guided by our rigidity measure. We validate our analysis and optimization on various assembly structures with fabrication.

Resources

Paper (preprint) [19.6M]

Fast Forward

Cite Us

@article{liu2022rigidity,

journal = {Computer Graphics Forum},

title = {Worst-Case Rigidity Analysis and Optimization for Assemblies with Mechanical Joints},

author = {Liu, Zhenyuan and Hu, Jingyu and Xu, Hao and Song, Peng and Zhang, Ran and Bickel, Bernd and Fu, Chi-Wing},

year = {2022},

publisher = {The Eurographics Association and John Wiley & Sons Ltd.},

doi = {10.1111/cgf.14490}

}

Acknowledgments

This work was supported by the Research Grants Council of the Hong Kong Special Administrative Region, China [Project No.: CUHK 14201921] and the European Research Council (ERC) under the European Union’s Horizon 2020 research and innovation programme (grant agreement No 715767 – MATERIALIZABLE). We thank the anonymous reviewers for their insightful feedback; Christian Hafner for proofreading and discussions; Ziqi Wang, Haisen Zhao, and Martin Hafskjold Thoresen for the helpful discussions; and the Miba Machine Shop at IST Austria for 3D printing the BUNNY and BOOMERANG models.